- Home

- Storage of Tapes

Magnetic Tape Storage

Proper magnetic tape storage at the recommended temperature and relative humidity conditions is required in order to prevent audio tapes or video tapes from degrading prematurely. With proper storage, the lifetime of this type of media can be extended many years.

The recommendations below are for polyester-based magnetic tape. This generally refers to audio cassette tapes, video cassette tapes, and video reels. It also includes audio reel-to-reel tapes after about 1970. Prior to 1970, many audio reel tapes used acetate as the base material. These tapes are much less stable and require digitization as soon as possible. If prompt digitization is not possible, then storage under cool and dry conditions will slow the chemical degradation of the acetate base material and extend the life of the tapes.

ISO Standard Storage Conditions

Storage conditions for polyester-base tape are divided into two general categories according to the ISO standard (ISO 18923-2000: Imaging materials – Polyester-base magnetic tape – Storage practices):

Medium-Term Storage Conditions – These are temperature and relative humidity conditions suitable for storing magnetic tapes intended to be maintained and kept for a minimum of 10 years.

Extended-Term Storage Conditions – These are temperature and relative humidity conditions suitable for storing magnetic tapes intended to be maintained for a minimum of 50 years.

The medium term storage conditions are for general short-term storage of audio tapes or videotapes, the extended-term magnetic tape storage conditions are the archival storage conditions.

Magnetic Tape Storage Medium Term Storage Conditions

The maximum temperature for magnetic tape storage should not exceed 23 degrees Celsius for prolonged periods. Short period peaks in temperature over 23 degrees Celsius may occur, but these peaks should never exceed 32 degrees Celsius. Do not store tapes lower than 8 degrees Celsius because there is concern of problems occurring related to the lubricant in certain tapes. This is especially a concern for older tapes, which used a lubricant different from modern tapes.

In terms of relative humidity, the average for polyester-base magnetic tape should be in the 15 to 50 percent range. Minimize the cycling of temperature and relative humidity as much as is feasible or possible. Generally, small fluctuations will not cause any issues, but avoid large and sudden changes in storage conditions.

Extended Term Storage Conditions

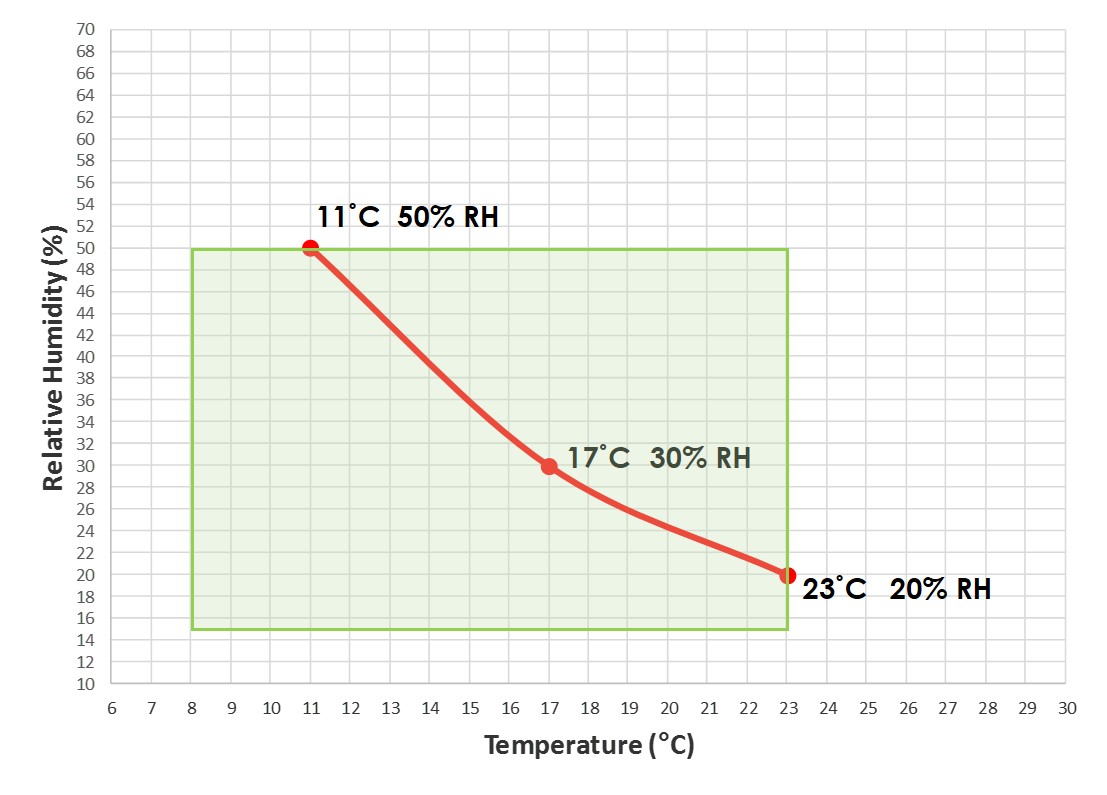

For these tape storage conditions, the ISO storage standard provides three temperature and relative humidity conditions to achieve the target of 50 years longevity. These three levels are listed below:

- Maximum temperature of 23 degrees Celsius and maximum relative humidity of 20 percent.

- Maximum temperature of 17 degrees Celsius and maximum relative humidity of 30 percent.

- Maximum temperature of 11 degrees Celsius and maximum relative humidity of 50 percent.

Note that higher storage humidity is allowed if the temperature is lowered or higher storage temperature is allowed if the humidity is lowered. When it comes to longevity, these two factors work opposite to each other and suitable storage conditions can be achieved by manipulating one variable or the other. Any of the three specific conditions outlined above will provide a minimum of 50 years life for the average tape.

The image of a graph shown below shows these temperature and relative humidity set points on a graph. As an approximation, any point along the line created by these three points or any combinations of temperature and relative humidity that fall on the line will achieve the longevity target for tape of a minimum of 50 years.

By choosing both lower temperature and lower humidity for magnetic tape storage, a lifetime greater than 50 years is obtainable. On the graph, this is represented by points below the line, but within the shaded box. For example, storage of tape at 11 degrees Celsius and 20 percent relative humidity will provide greater that 50 years longevity. With the selection of higher temperature and relative humidity set points (i.e. above the line but within the shaded box), the lifetime is less than 50 years and decrease with higher temperatures and relative humidities.

As with the medium term storage conditions, avoid temperatures less than 8 degrees Celsius and relative humidities less than 15% (storage conditions outside of the shaded box), when storing polyester-based tapes. Minimize fluctuations in temperature and relative humidity as much as possible.

Note that when storing tape cold, special precautions are needed to prevent condensation from forming on the tapes. This means slow warm up times or ensuring the tapes are placed in sealed plastic bags prior to exposing them to a warmer environment. Usually tapes are conditioned to a drier environment and then placed in sealed freezer bags (with all the air squeezed out of the bag) prior to placing them into cold or cool storage.

Finally, tapes that are poorly manufactured will benefit substantially more that those that are well made. Well manufactured tapes will still benefite from good storage conditions but they are inherently more stable.