- Home

- Damage and Repair

- DVD Repair

DVD Repair

DVD repair of scratches can be performed in several different ways. However, most of the scratch repair methods do not solve the DVD scratch problem.

Scratches on DVDs may occur on the top side of the disc (label side) or the base side of the disc.

Top Side Versus Base Side Scratches

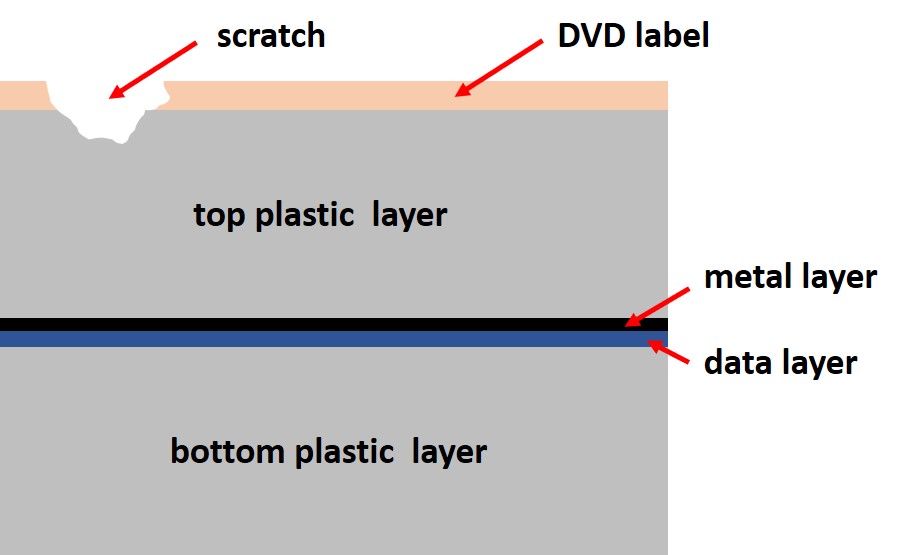

Top side scratches to DVDs will not damage the metal layer because the metal and data layers are sandwiched in the middle of the disc structure. This is evident when examining the schematic diagram below.

Obviously, the data layer is important because it contains the information that the user wants. The metal layer is important because it makes the disc readable. It reflects the laser light back to a photodetector in the drive after reading the data layer. This allows the reading of the DVD information and therefore, is an important part of the disc structure and it must remain undamaged. For metal layer damage in a DVD, the DVD scratch would have to be very deep and if this occurs, usually a cracked or broken disc is the result. This page focuses on DVD repair of scratches on the base side of these discs. Note that these repair methods are usable on CDs as well.

Types of Scratches

Scratches may or may not cause problems when you play your CDs and DVDs. Whether they do cause problems depends on the size of the scratch, the depth of the scratch, and whether the scratch is radial or circular. Circular scratches are very problematic because this creates bad data in a sequence and the error correction system of the optical disc technology cannot deal with this situation well since it relies on adjacent data to fix the bad data. Radial scratches create more of a random distribution of errors and the error correction system handles this situation well. Also, if scratches are small and not deep, DVD repair is likely not necessary because these small scratches will not affect the laser light path that reads the disc.

If DVD scratches do affect the performance of the disc, then a remedy is required to make the discs playable once again without problems. There are basically three types of repair solutions: fillers, polishers, and sanders.

Fillers for Scratch DVD Repair

Fillers are liquid substances applied onto the disc to fill the scratch or gouge. Products are available commercially and many suggested homemade type remedies exist. The key principal is that the filler is supposed to have the same refractive index as the polycarbonate base so that the laser light is not affected by the scratch as it reads the disc or in other words the scratch behaves just like the rest of the disc base and is unnoticed.

Fillers that have this property are difficult to find and fillers often flake out of the filled scratch and contaminate the drive as the disc spins at high speed in a heated environment. Overall, scratch fillers are not effective at all for DVD repair of scratches and will do more harm than good.

Polishers for Scratch Repair

Polishers are liquid solutions sold commercially and applied to the disc base to polish out the scratch. The goal is to smooth out the large problematic scratch. Usually what occurs is that a lot of smaller scratches form because of the treatment and the larger scratch may or may not be remedied. Bottom line is that polishers may help remedy the scratch to some degree, but often this technique makes things worse. If you have no other option for DVD scratch repair, then DVD polishers may be worth a try, keeping the above stated risks in mind.

Sanders for Scratch Repair

Sanders are pieces of equipment specially designed for CD or DVD scratch repair. You often find these in stores that sell used CDs or DVDs. This is how these stores restore problem discs that they acquire and they also offer this sanding scratch repair of optical discs as a service with cost depending on the severity of the scratch. In summary, this scratch treatment works by sanding the polycarbonate plastic base down to the level of the scratch, thereby eliminating it. Sanding of the whole base occurs with fine sandpaper, not just the area of the scratch. After sanding, the disc base is repolished so that it is crystal clear once again.

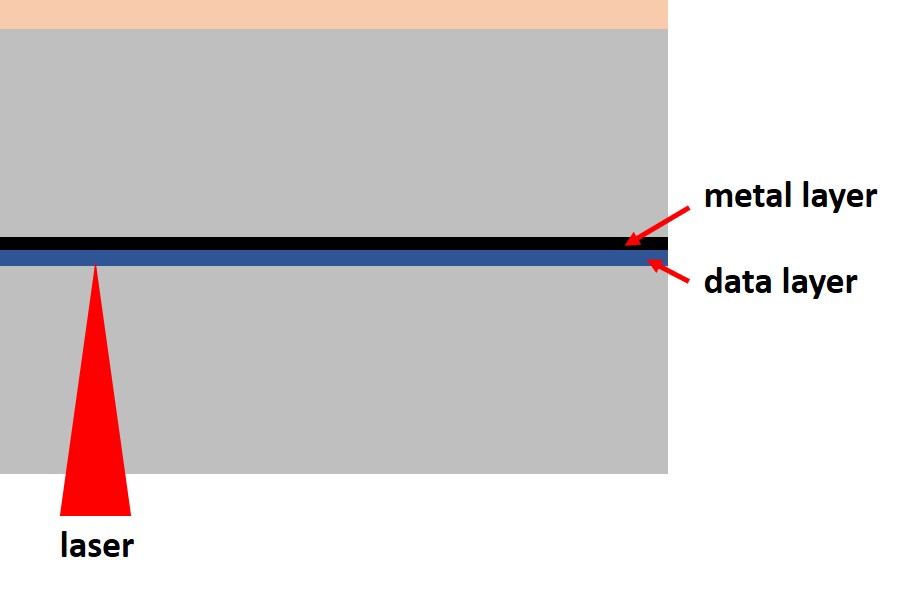

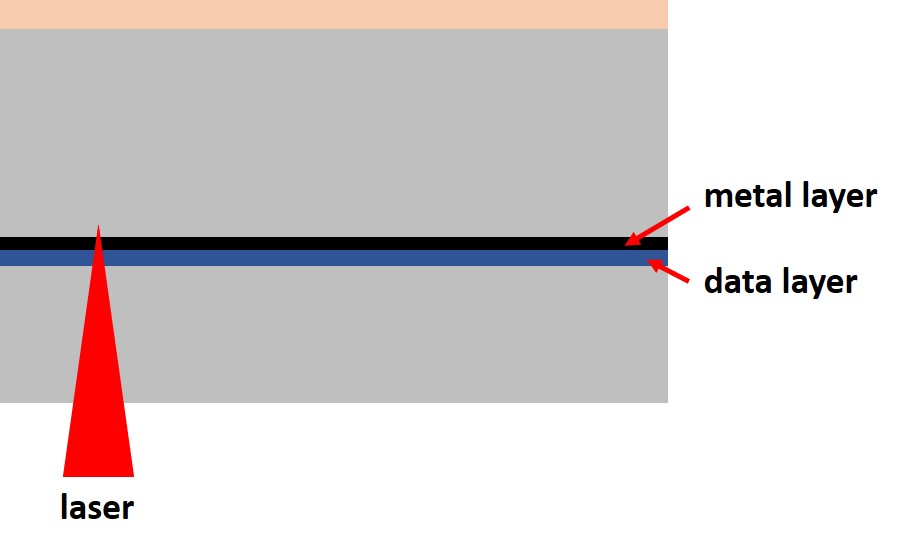

This method of DVD scratch repair may or may not work. The main problem is the thinning of the base layer and this affects how the laser light interacts with the disc when reading the disc. Disc manufacturing is to exact specifications to function properly and changing these specifications can result in problems. The schematic diagrams below illustrate this point.

In the first image, the reading laser focuses precisely on the data layer. However, because of the thinner plastic of the base layer (as shown in the lower image), the laser light no longer precisely focuses on the data layer and depending on the amount of misfocus, disc read problems may occur.

This method is the most expensive of the scratch repair techniques and may lead to more problems with the disc. However, it is probably the best shot at restoring a disc that will not play because of scratches.

With any of these scratch DVD repair and scratch CD repair methods, use them only as a last resort, when you have a scratched disc that simply will not play in a few different players or drives.