- Home

- Storage of Discs

- CD Label Printer

CD Label Printer – Inkjet or Thermal Transfer

A CD label printer identifies the information recorded on a CD or other optical disc. The two main types of disc or CD printers are inkjet and thermal transfer.

However, before discussing these disc labeling methods, it is useful to review the other disc labeling options.

CD Labeling Methods

Perhaps the easiest and cheapest disc labeling method is to write on the disc with a water based permanent felt marker. For CDs, writing should be limited to the hub area of the disc, which unfortunately does not provide a lot of space for identifying information. For DVDs and Blu-rays, because the information and metal layer of the discs are further away from the top surface of the discs, writing on any area of the top side is acceptable.

Another labeling method other than a CD label printer is using adhesive stick-on labels. Although these labels for disc labeling are readily available, their use is not recommended by the optical disc storage standard and experts in the field because they will affect disc performance in the short term and can seriously damage discs, especially compact discs, in the long term.

LightScribe was a type of CD label printer using special discs, LightScribe design software, and LightScribe compatible drives. This type of disc labeling is no longer available.

Finally, silk-screening is a CD labeling method. Commercially available discs such as audio CDs, software discs, movie DVDs, and others, utilize this type of CD label printing. The manufacturer places this label on the disc, whereas the labeling methods discussed above and the CD label printer described below are utilized by the consumer.

CD Label Printer Inkjet

One type of CD label printer is an inkjet printer. Inkjet printing is common for printing text documents and digital photographs, but some inkjet printers are adapted to print on optical disc media. Not all types of CDs, DVDs, or Blu-rays are compatible with inkjet printers. The discs require a special printable surface that can accept the ink and hold it in place. Spraying of the ink onto the disc surface is via small droplets. The surface of these discs is usually identified by their white or off-white matte textured surface.

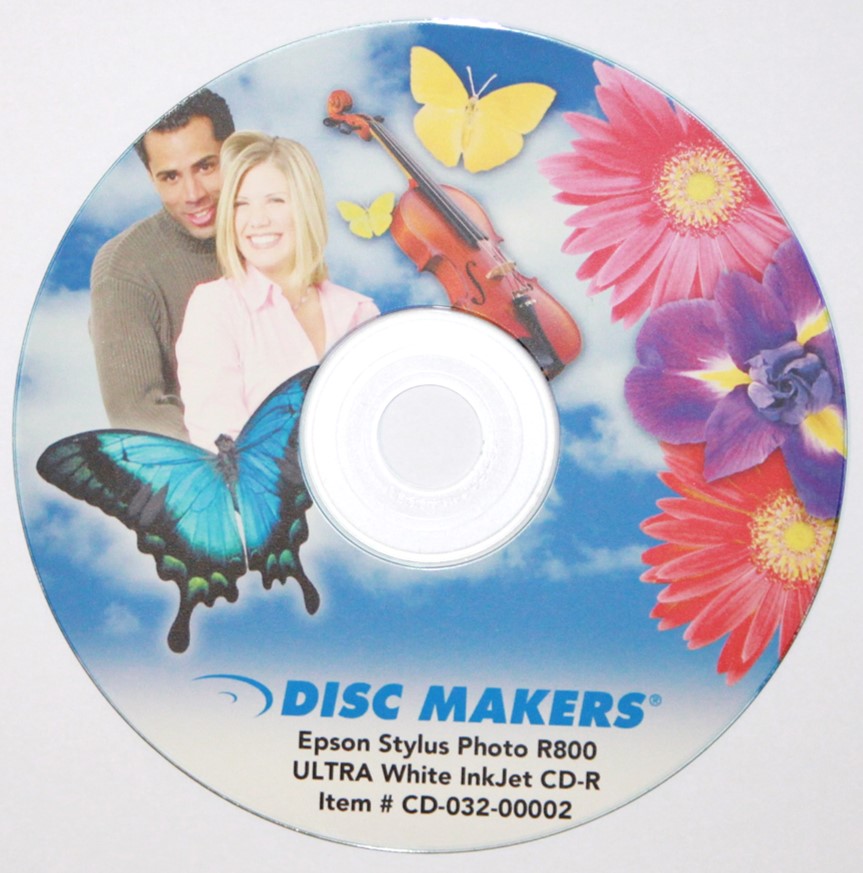

This type of label printer can produce nice looking labels as shown in the image below.

However, the problem is that the label is not waterproof or moisture resistant. Contact with moisture or water can cause the inks to run, thereby destroying the label. A special coating on top of the printed label is required to increase the durability. Another problem is little information exists as to the effect of the inks and ink solvents on the long-term stability of optical discs, especially CDs.

CD Printer Thermal Transfer

In thermal transfer printing, the coated side of an ink ribbon, heated by a print head, is pressed up against the top surface of the disc. The heat melts the ink and adheres it to the surface of the disc. For this CD label printer, special disc surfaces are not a requirement, although often you will find the optical discs intended for printing by this process have unlabeled surfaces.

The thermal transfer printers used on CDs and other optical discs are specially designed for this purpose and are different than those used for printing on paper.

As shown below, the labels produced by this CD label printer are professional looking.

They are also very durable and resistance to water, moisture, and rub off. As for the inkjet printing method, there is uncertainty as to the long-term effects that thermal transfer printing has on optical disc media, especially CDs. As stated in the storage standard for optical discs (ISO 18925), thermal printing has been known to damage data stored on the disc if the applied heat is too great. However, no scientific research exists to established whether there are significant problems with this CD label printer method.