CD DVD Replication Services

CD DVD replication services are used when many discs with the same content need to produced for the purpose of widespread distribution. For smaller amounts of discs, CD DVD duplication services are more cost effective.

When to use Replication

To be more specific, when the production of less than 500 discs is necessary, then it is better to go with CD DVD duplication in most cases. With 500 to 1000 discs, then either duplication or replication may be a good choice. This depends on the requirements of the job and what the duplication or replication company is charging for those requirements and disc quantities. For over 1000 discs, CD DVD replication services are almost always the right choice.

What are CD DVD replication services?

CD replication or DVD replication is a process that creates CD or DVD disc media like the commercially available audio CDs or software CD-ROMs or DVD-ROMs. Unlike CD DVD duplication where recordable media such as CD-Rs or DVD-Rs are used, replication involves creating the discs from scratch or from the raw materials.

A summary of the process is as follows. The client sends the information to be placed on the CD or DVD disc to the CD DVD replication services company. From this digital information, a glass master with pits in it, which represent the digital information, is made. From this master, a series of metal stampers (also containing the pits, which represent the digital information) are created. Injection of soft polycarbonate plastic into a mold follows and then disc stamping or in other words the information is embedded in the polycarbonate plastic in the form of small pits. Replacement of the stampers occurs periodically to ensure the pits are always well formed.

Next, coating of the side of the polycarbonate disc containing the pits occurs with a thin metal (which reflects the laser light in the player back to the detector to register a signal when reading the disc) in a process called metallization. A protective lacquer coating is applied via a spin coating technique and cured with ultra violet light. This layer is important because it protects the metal layer and allows the labeling of the disc.

Finally, a silk-screened label is applied, which is the usual labeling method used by most companies but some companies also offer Offset Litho printing for high quality images on the disc. This completes the production of the disc.

The typical turn-around time for CD DVD replication is 7 to 10 days compared to about 3 days for CD DVD duplication.

It is evident that the replication process is quite expensive to set up and would only be cost effective for producing large quantities of discs. In fact, when manufacturing many discs, the cost per disc is quite low for CD replication or DVD replication. Producing the glass master and metal stampers are expensive and time-consuming processes and only become feasible when the costs can be spread over a large quantity of replicated CDs or DVDs.

Options for Replicated Discs

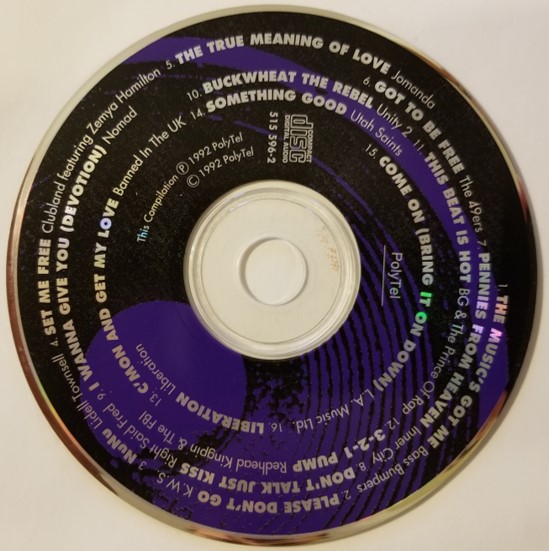

CD DVD replication services offer a variety of silk-screen labeling options with choices of one or several colors on the label. Different packaging can be selected such as plastic sleeves, paper sleeves, cardboard sleeves, thin jewel cases, regular jewel cases, shrink wrapping, etc. An example of a replicated disc in packaging is shown below. Replicated discs such as this AOL disc were produced in the millions and distributed free of charge for promotional purposes.

Some companies also produce mini CDs or mini DVDs or CDs and DVDs in different shapes than the standard discs. Finally, insert materials can be printed by the CD replication or DVD replication company. Some companies will also perform the distribution of the final replicated disc product for the client.